Bryan Laidlaw

Heating Engineer

Granton

Granton

Energy Center

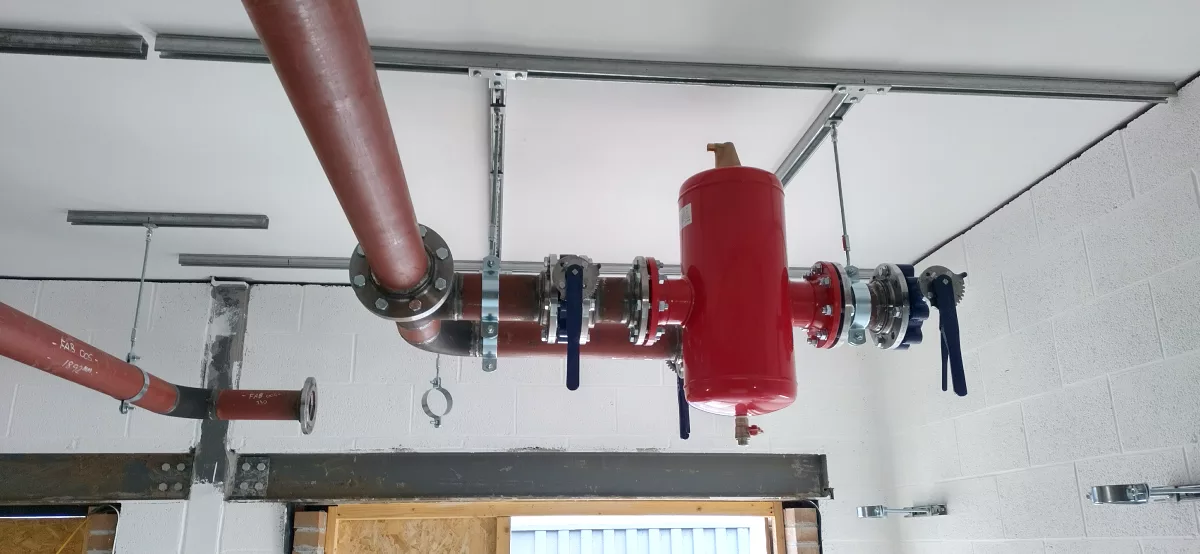

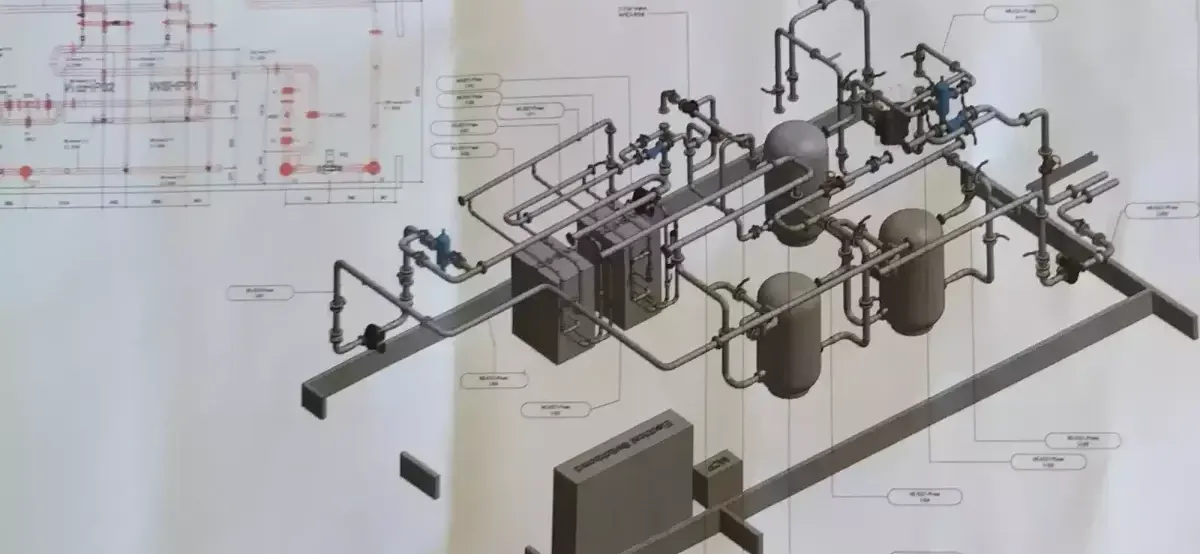

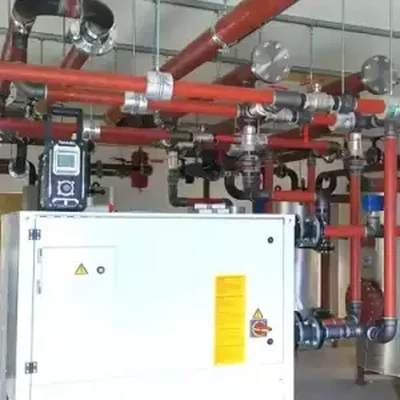

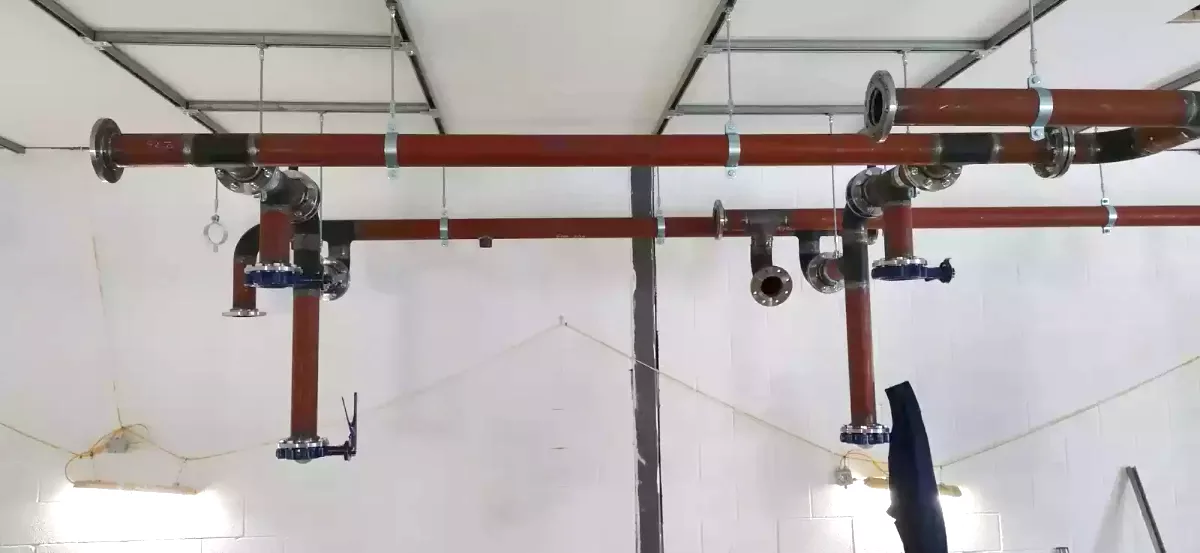

A medium sized energy center fitout with all pipework prefabbed offsite. Pipe sizes ranged from 4 inch down to 1/2 inch. The majority of the fitout was bolting together spools with a bit of screwed work tying in the plant. The project went well, proceeded without major issues and was completed ahead of schedule.

There were some delays due to the wait for spools. Some of the spools arrived out of order, which hindered the installation process. Additionally, a significant number of spools required alterations due to the pump flanges being of the wrong table. Despite these challenges, the fitout progressed relatively smoothly. A final push to fit the air source heat pumps, ready for a pressure test and the jobs complete.

.webp?h=7d51ce1c08e8ca121f87df925e9b4cba)