Bryan Laidlaw

Heating Engineer

Edinburgh

Edinburgh

Art College

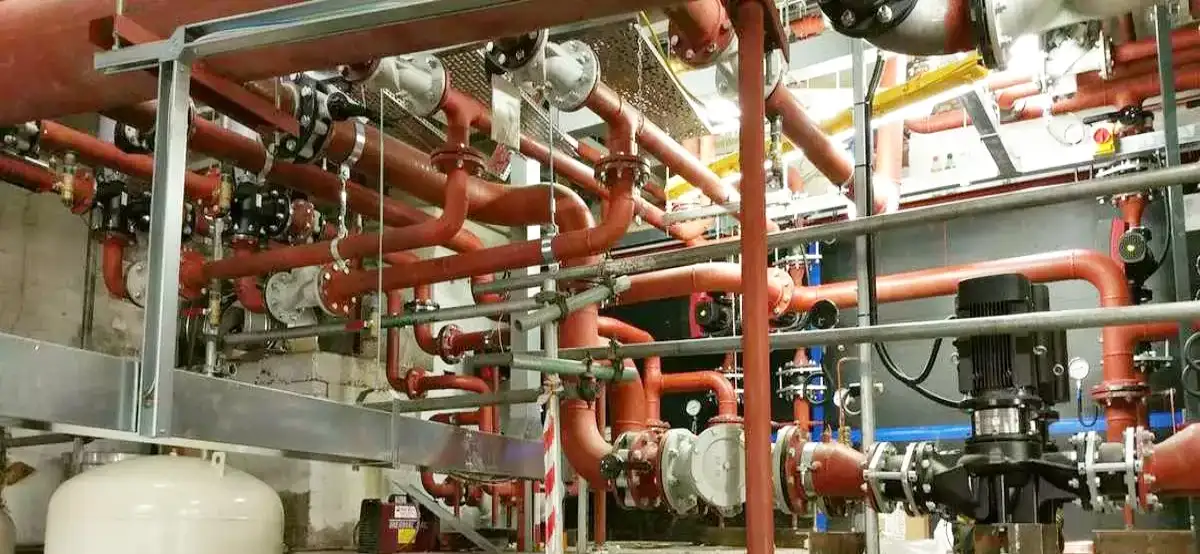

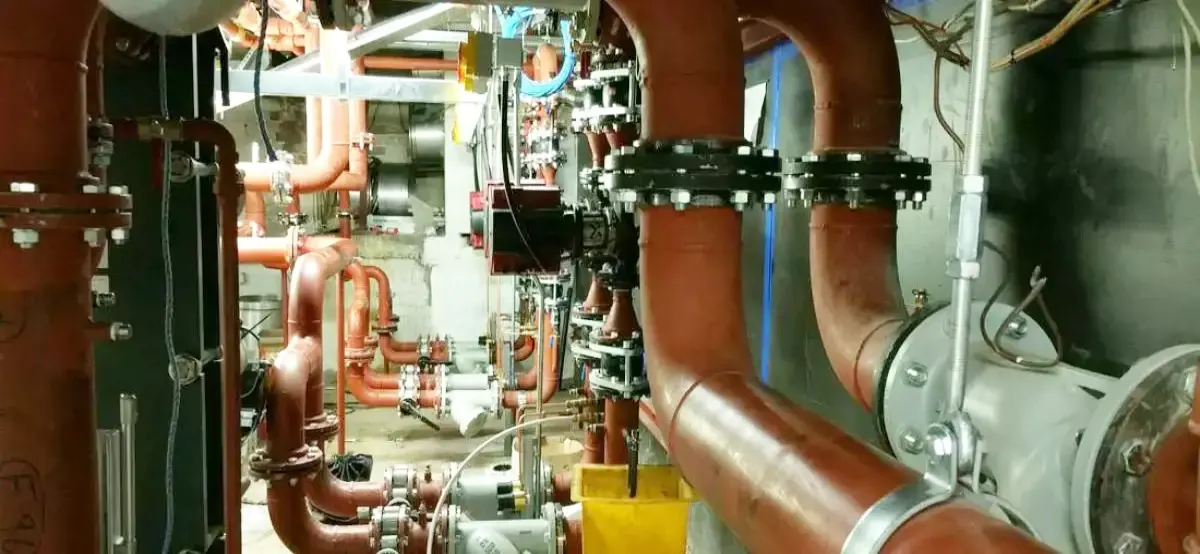

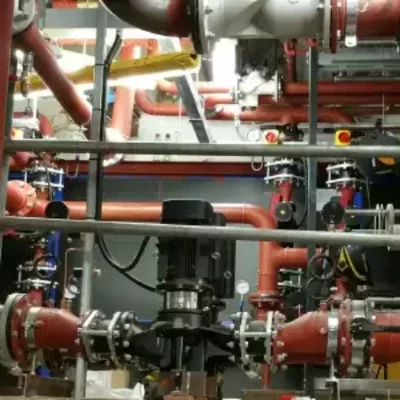

The Edinburgh art college was a 2 year project completed over 2 phases. The first phase of the contract comprised of a full system strip out and new heating system installation. The new installation involved fitting a rooftop plantroom, 3 air handling units, new heating mains pipework, radiator circuits and all new radiators.

What I

What I

Worked On

Throughout the project I was the main welder. Phase 2 involved the prefabrication of all the boilerhouse pipework off site. Pipe sizes ranged from 12 inch down to 2 1/2 inch. Upon completion the prefabricated sections were assembled in the boilerhouse and piped up to the new plant.

- phase 2

- Welding Of All Prefabricated Sections For The New Boilerhouse

- Fitting 4 Pump Sets

- Fitting A Plate Heat Exchanger

- Fitting 5 Pressure Vessels & The Press Unit

- Piping The Primary Side Of The Domestic Cylinders

- Testing Of The Boilerhouse Pipework

Once the boilerhouse installation was complete it was tested to 7 bar, commissioned and fired up without any problems.

.webp?h=61dd5438d7edca75570dd8ce27639315)